Hat Top Ridge Vent for Efficient Ventilation

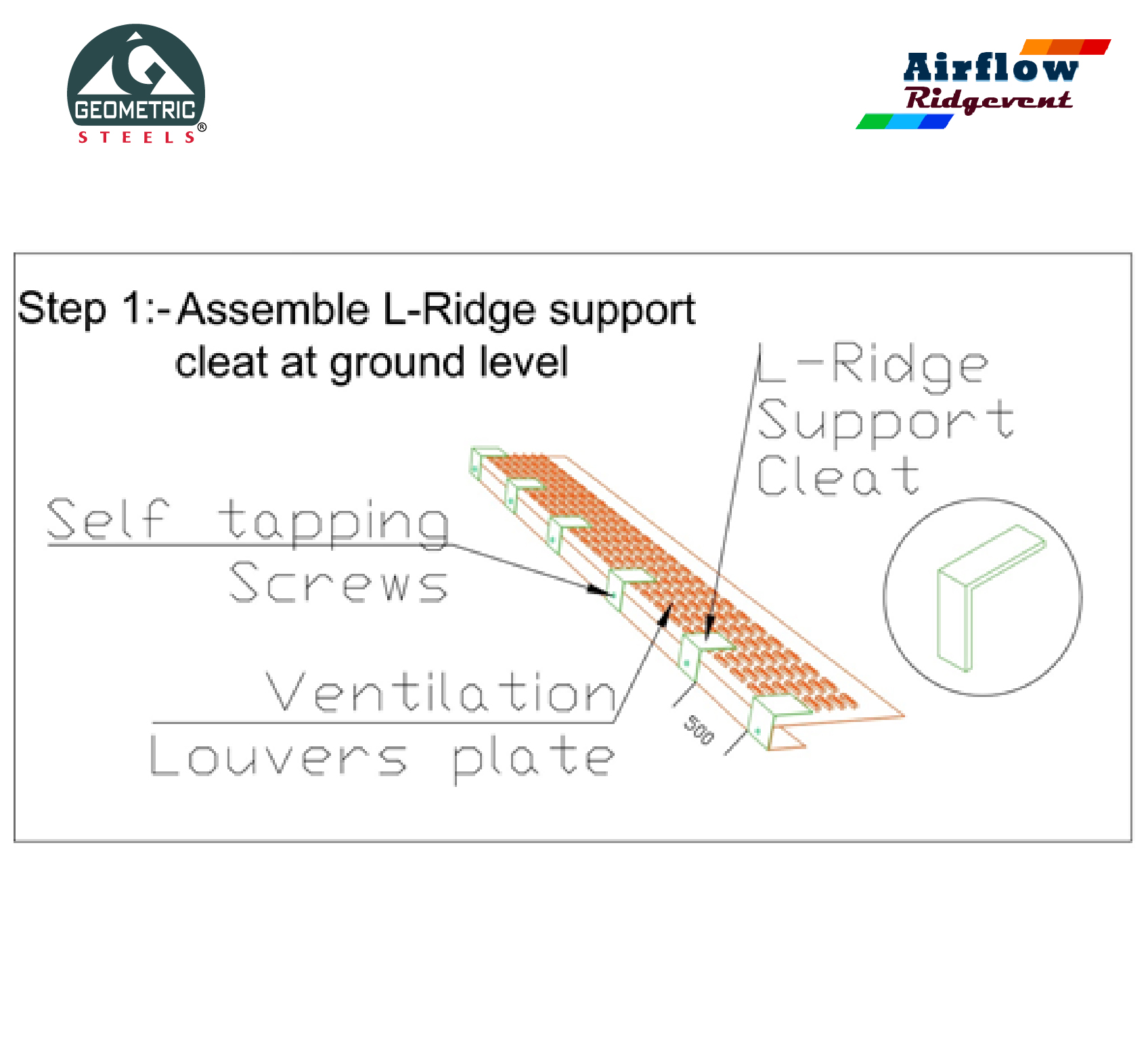

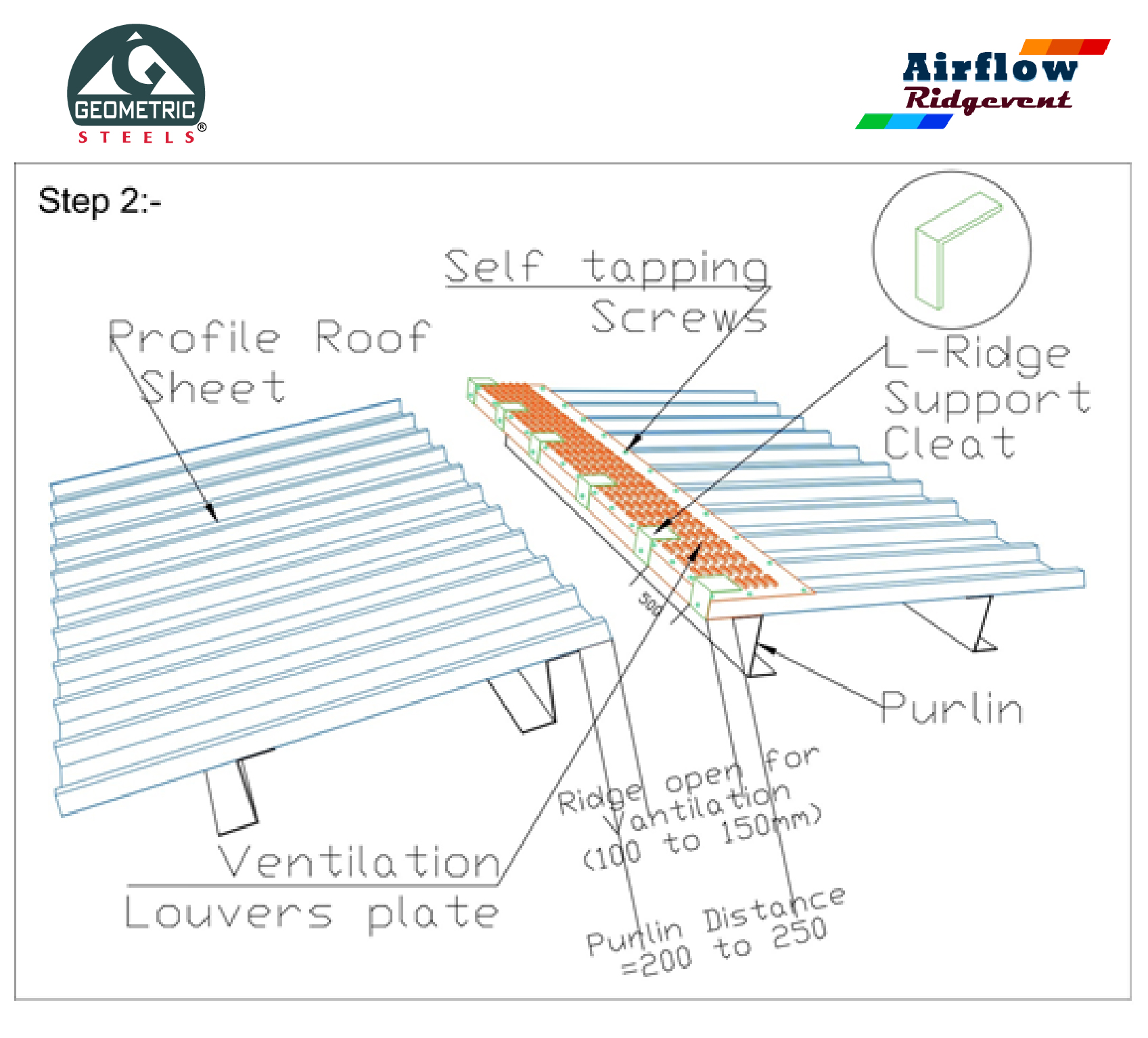

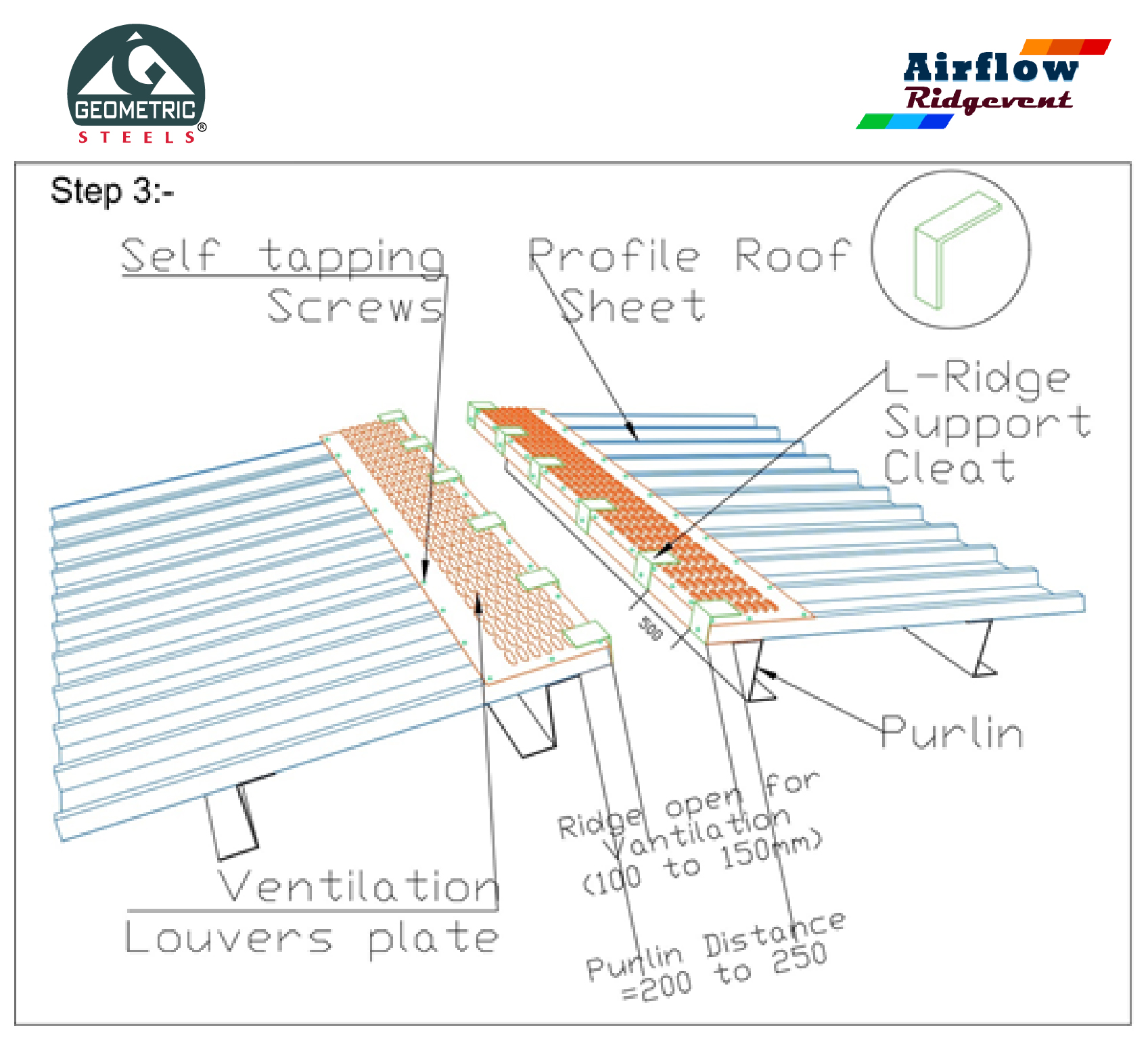

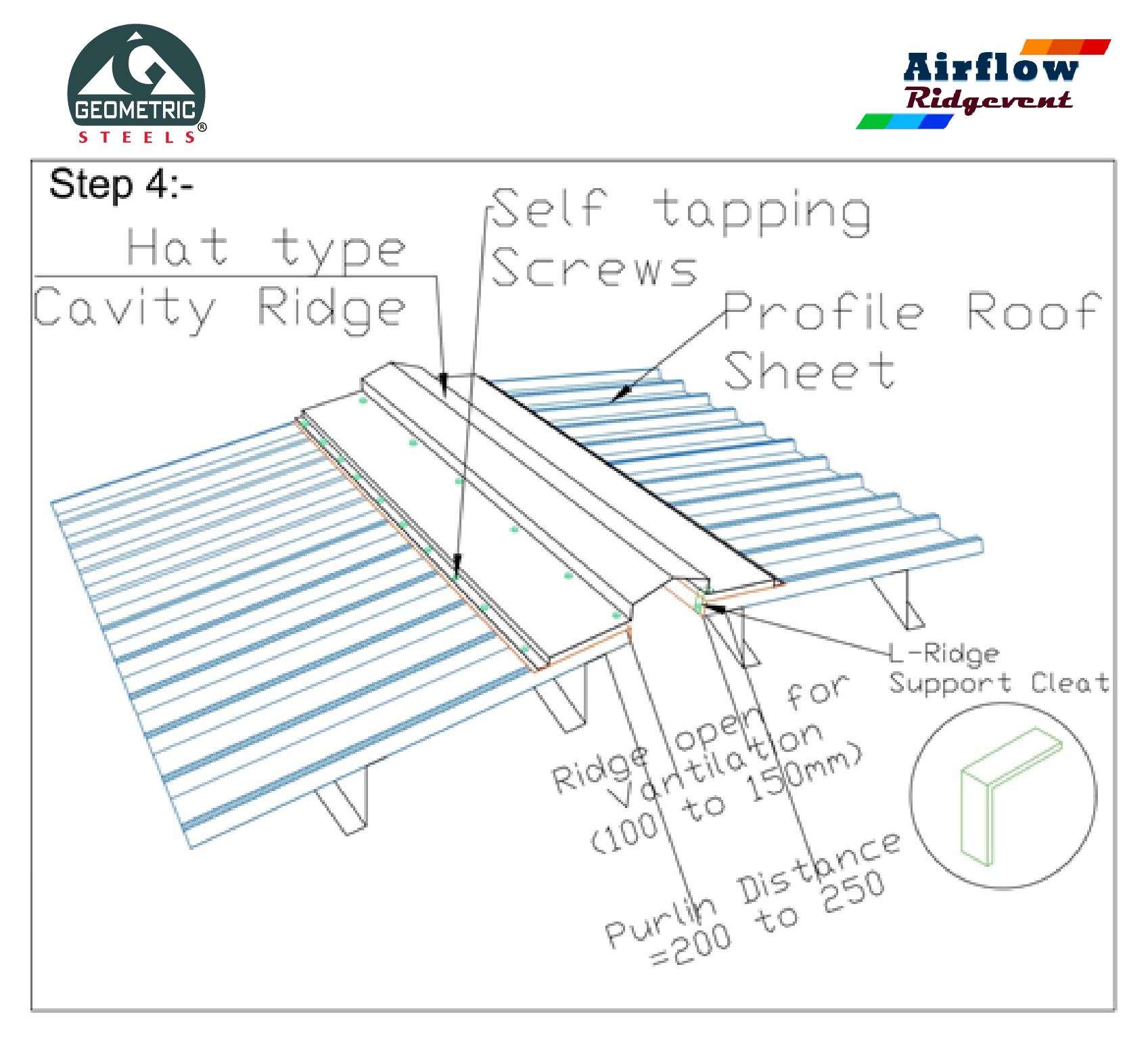

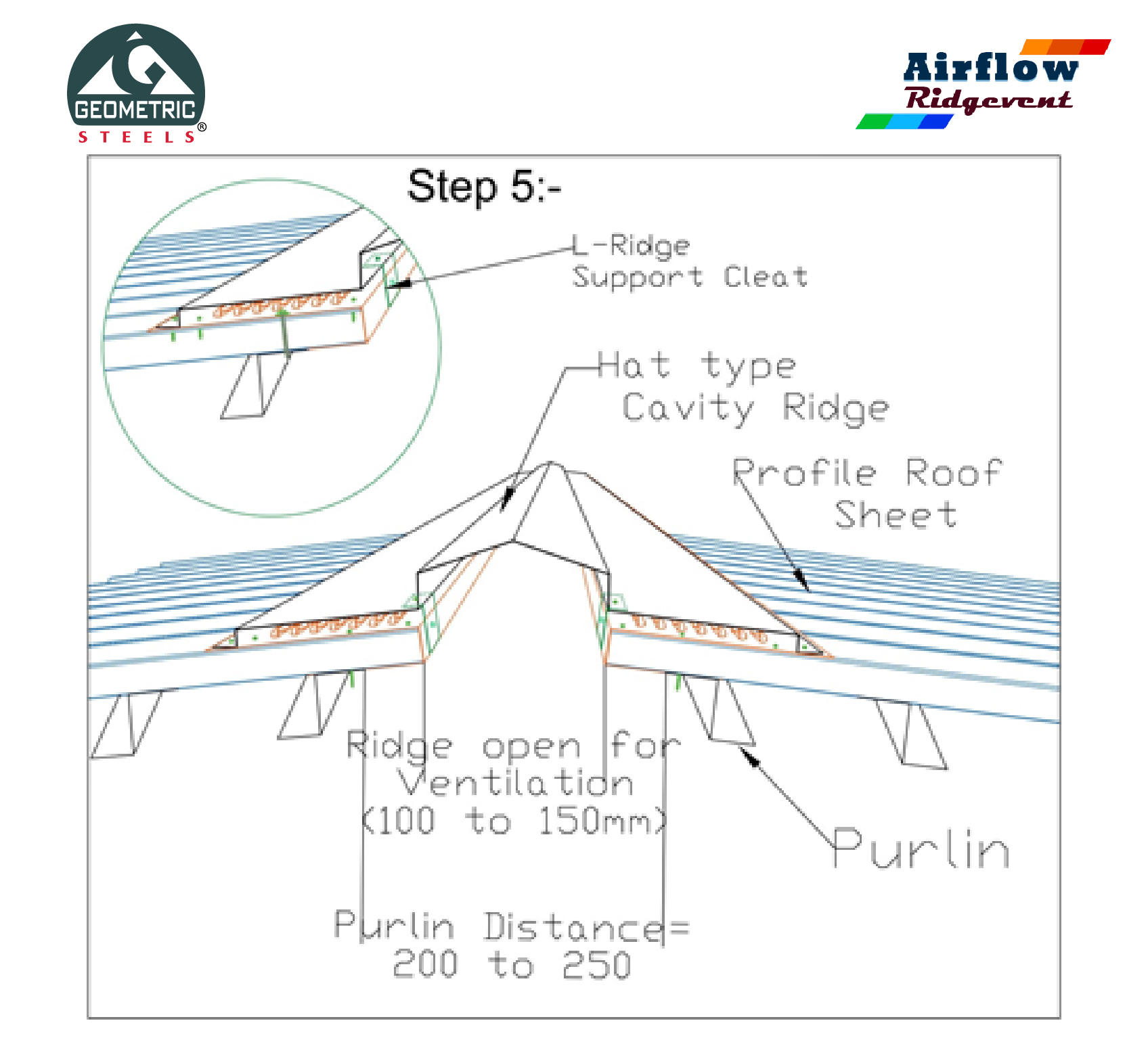

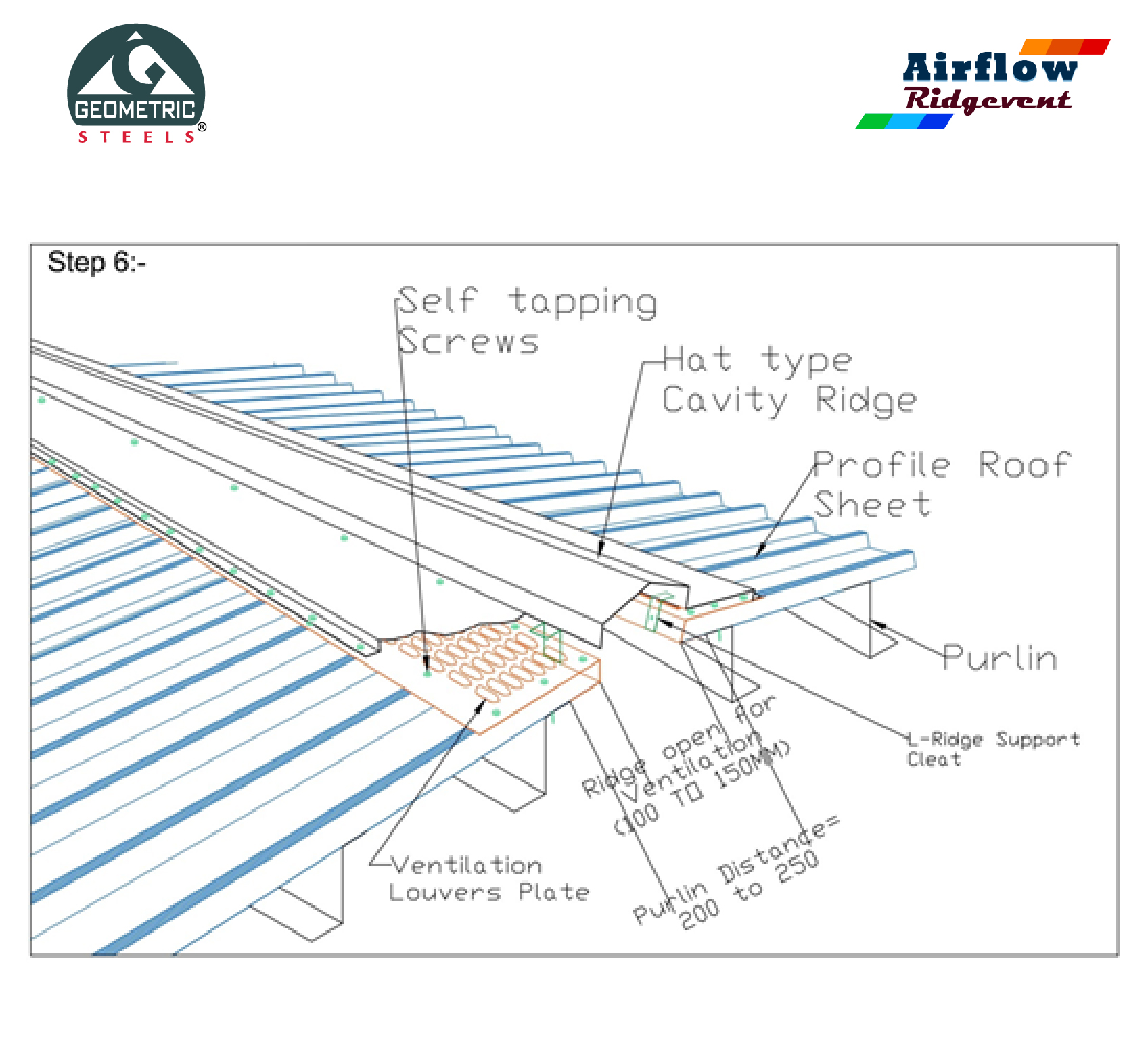

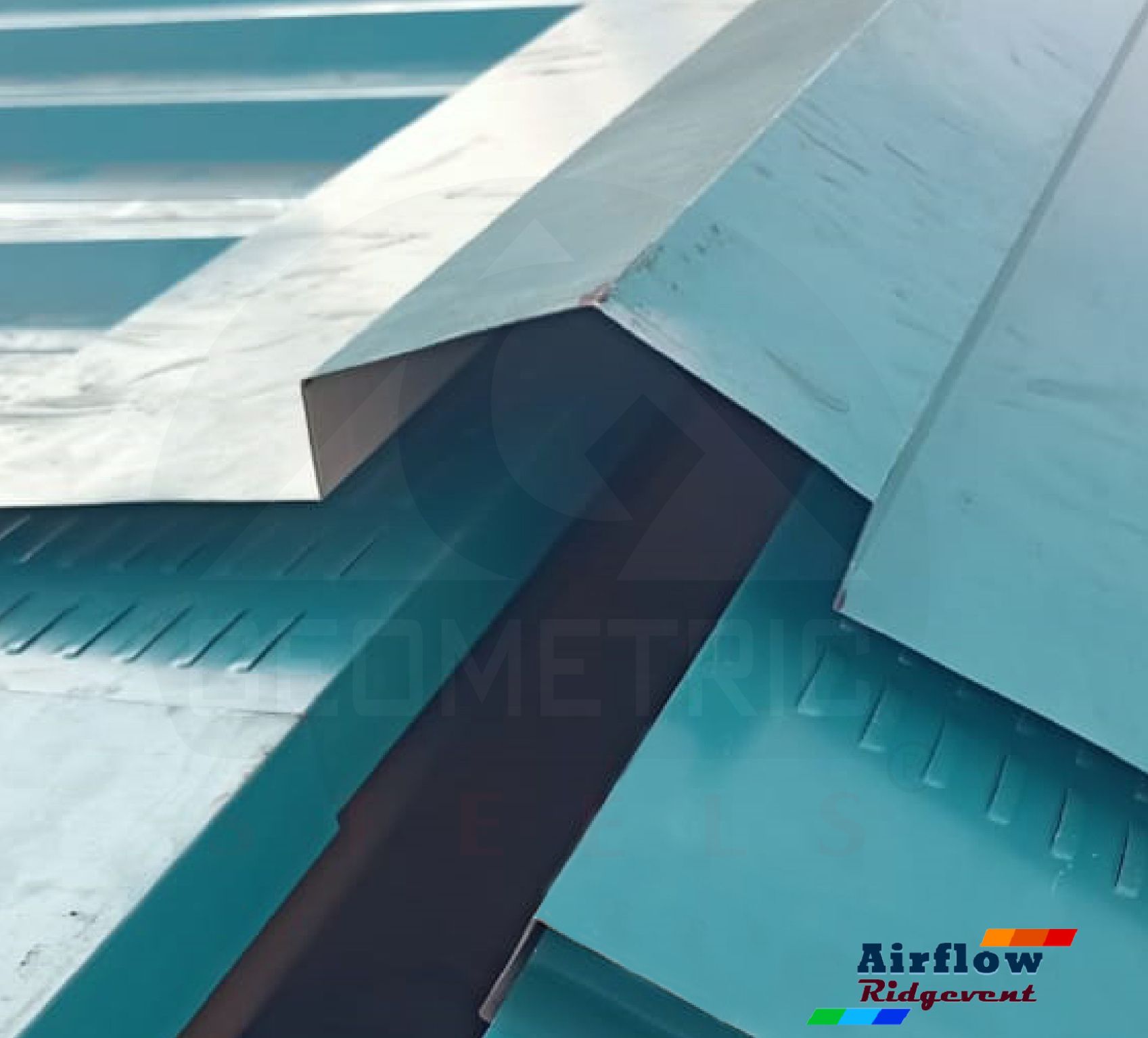

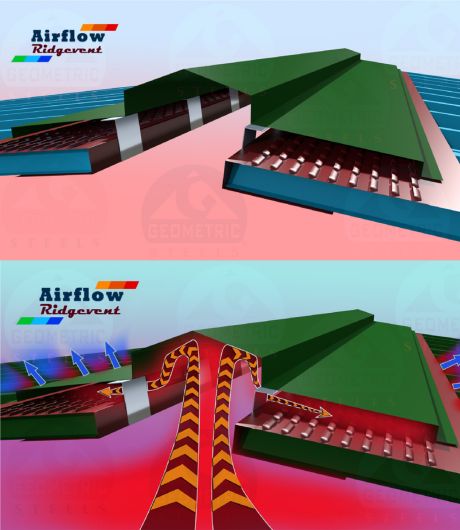

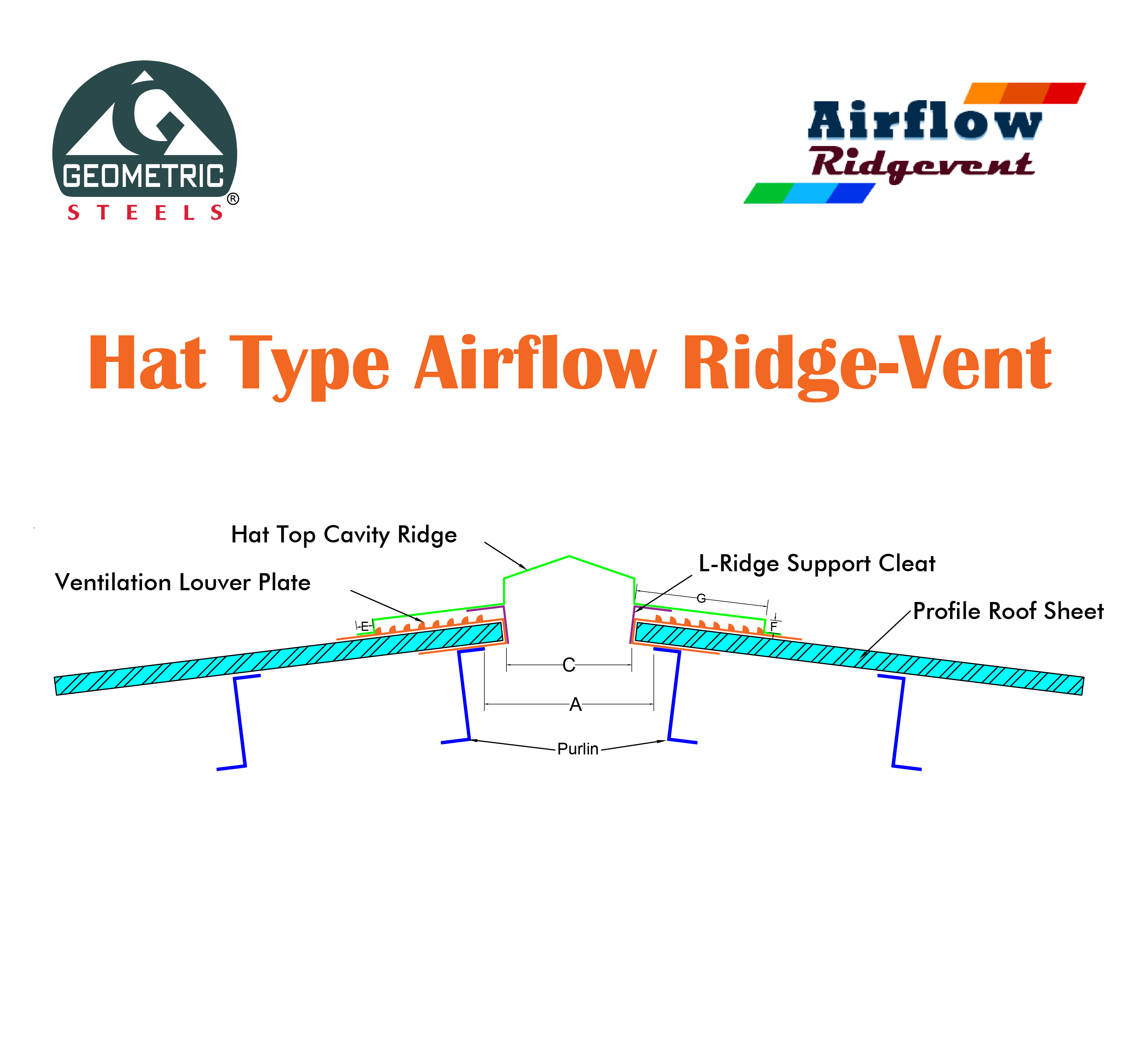

The Hat top Airflow Ridgevent comes with two louvers exhaust plates in parallel with the roof slope the characteristic hat-style cavity Ridge made with colour coated galvanise, Colour coated Galvalume and galvalume according to the specifications of the customer. Hat Top Airflow Ridgevent is simple to install on any roof profile design and also on older profiles. It's maintenance-free due to the long life-cycle of performance.

FEATURES AND BENEFITS

- Continuous High natural airflow

- Five meters of Airflow Ridgevent is equivalent to 2 whirlybirds

- Internal pressure of structures decreased.

- It is available in Colour coated steel and can be installed on all roofing profiles.

- Available in Colour coated steel and all roofing profiles

- Improves & maintains a comfortable living environment

- No power, moving parts, or noise

- Maintenance-free (No clogging)

- Maintains a clean, attractive roofline – hidden underneath louvers ridge cap

- Extends the life of the building through natural air circulation

- Actively prevents the build-up of mould within the ceiling cavity – numerous health benefits

- Located precisely where they do the most good, at the peak of the roof, Airflow Ridgevent are virtually invisible from ground level and they provide greater airflow than other vents

- Easy to install on existing old roofing ALSO

- Maximum effective utilization of space with an existing arrangement of structure.

- Made in INDIA

| Throat (C) | Purline Distance (A) | (G) | (E) | (F) |

|---|---|---|---|---|

| 100 | 200 | 157 | 20 | 15 |

| 150 | 250 | 157 | 20 | 15 |