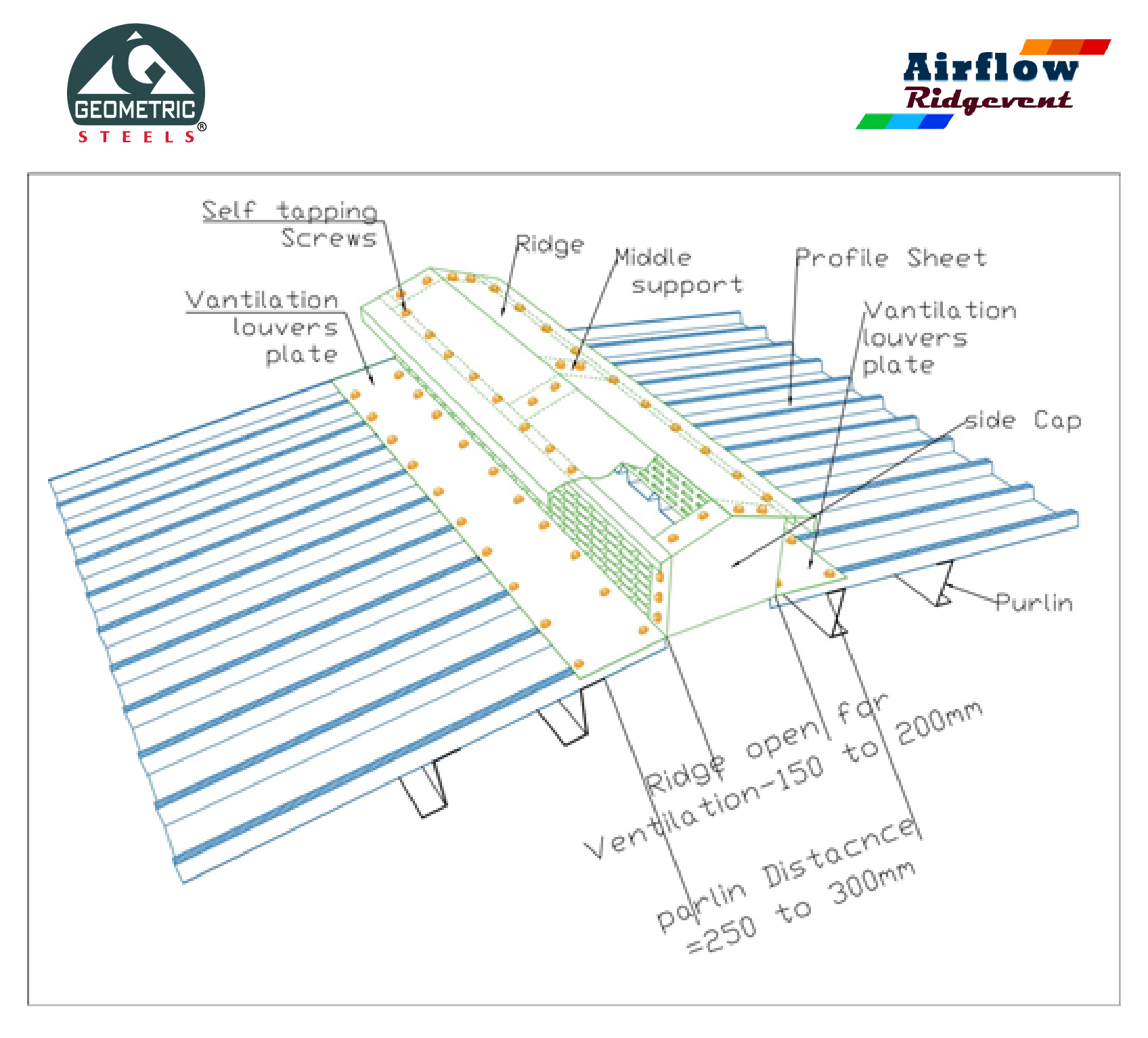

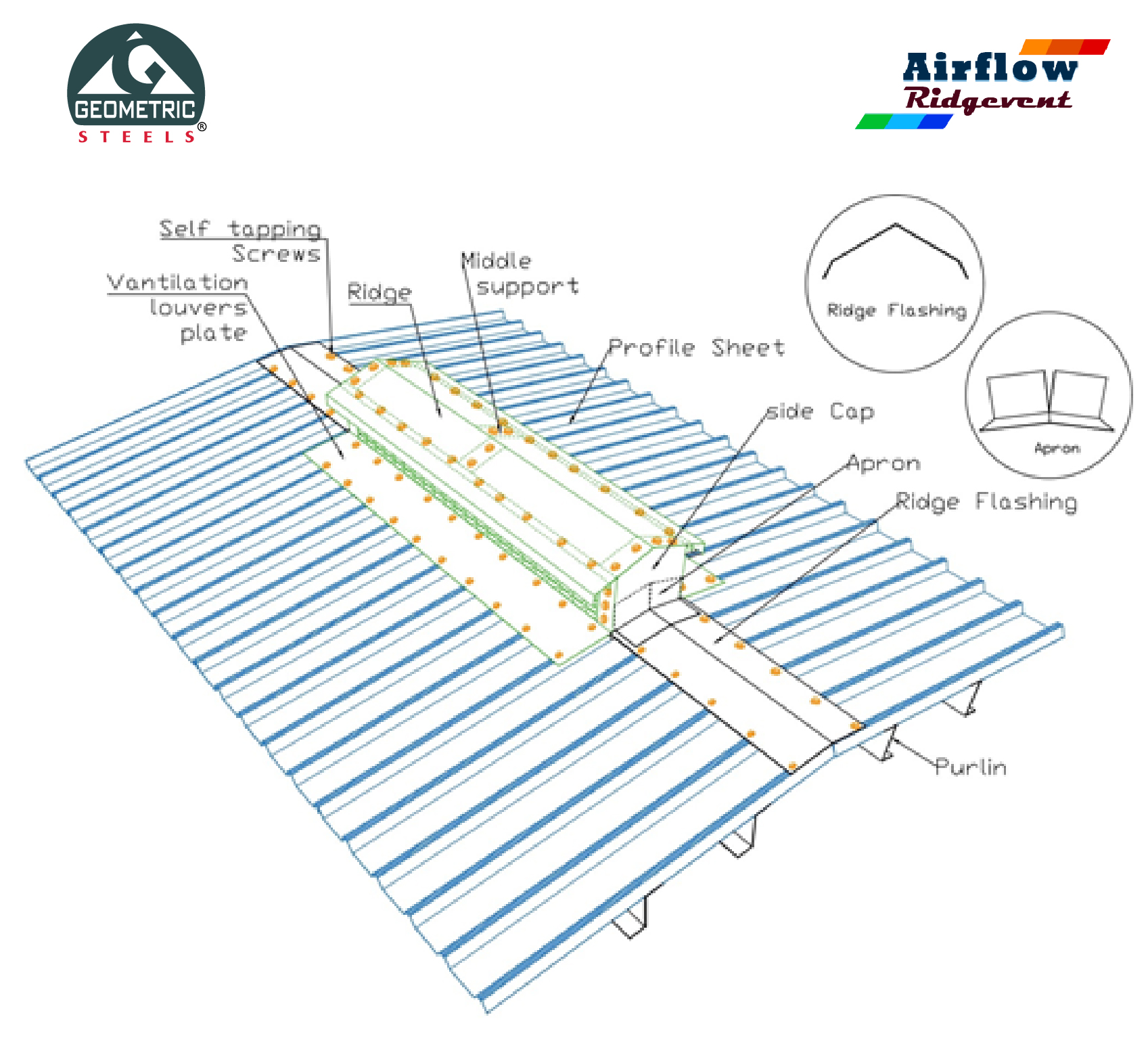

Monitor Type Airflow Ridge Vent Design

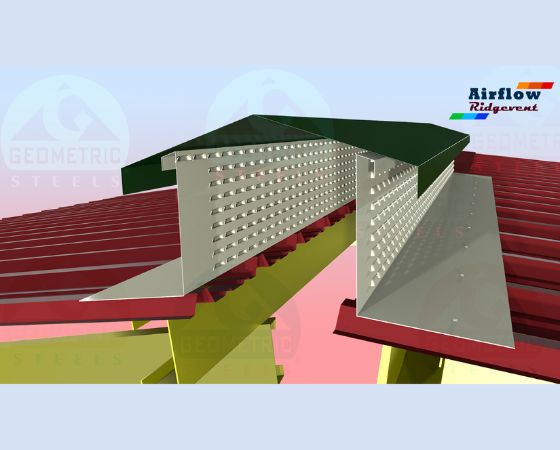

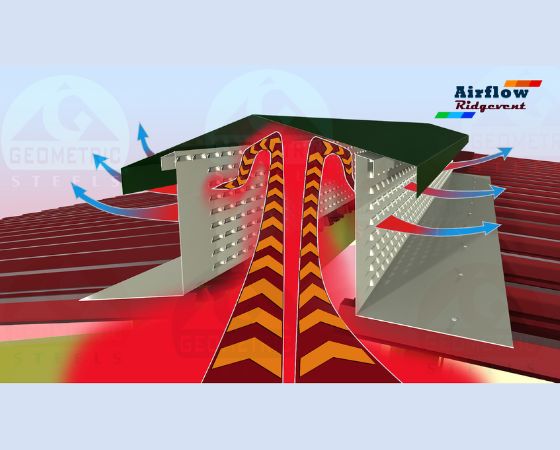

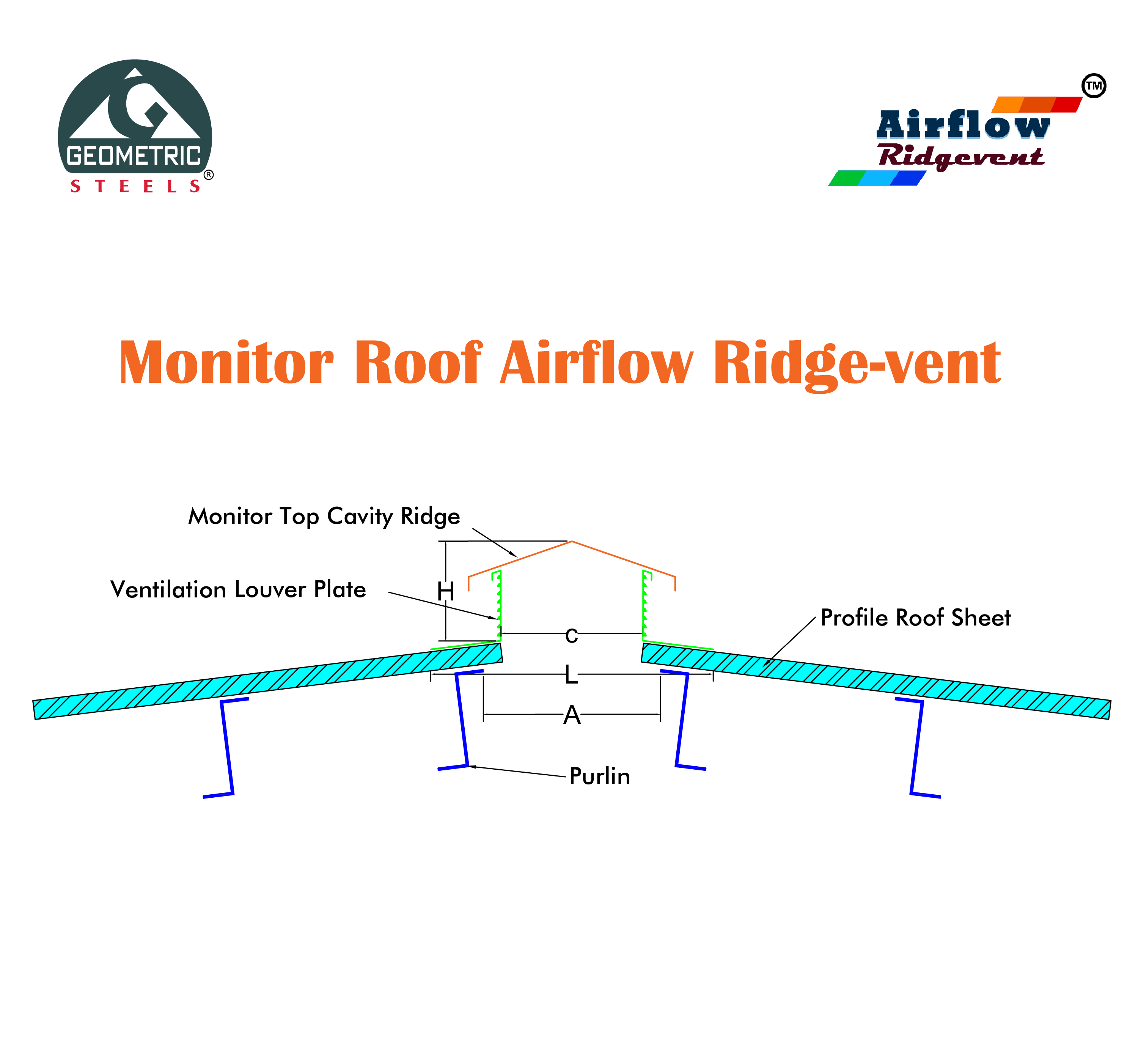

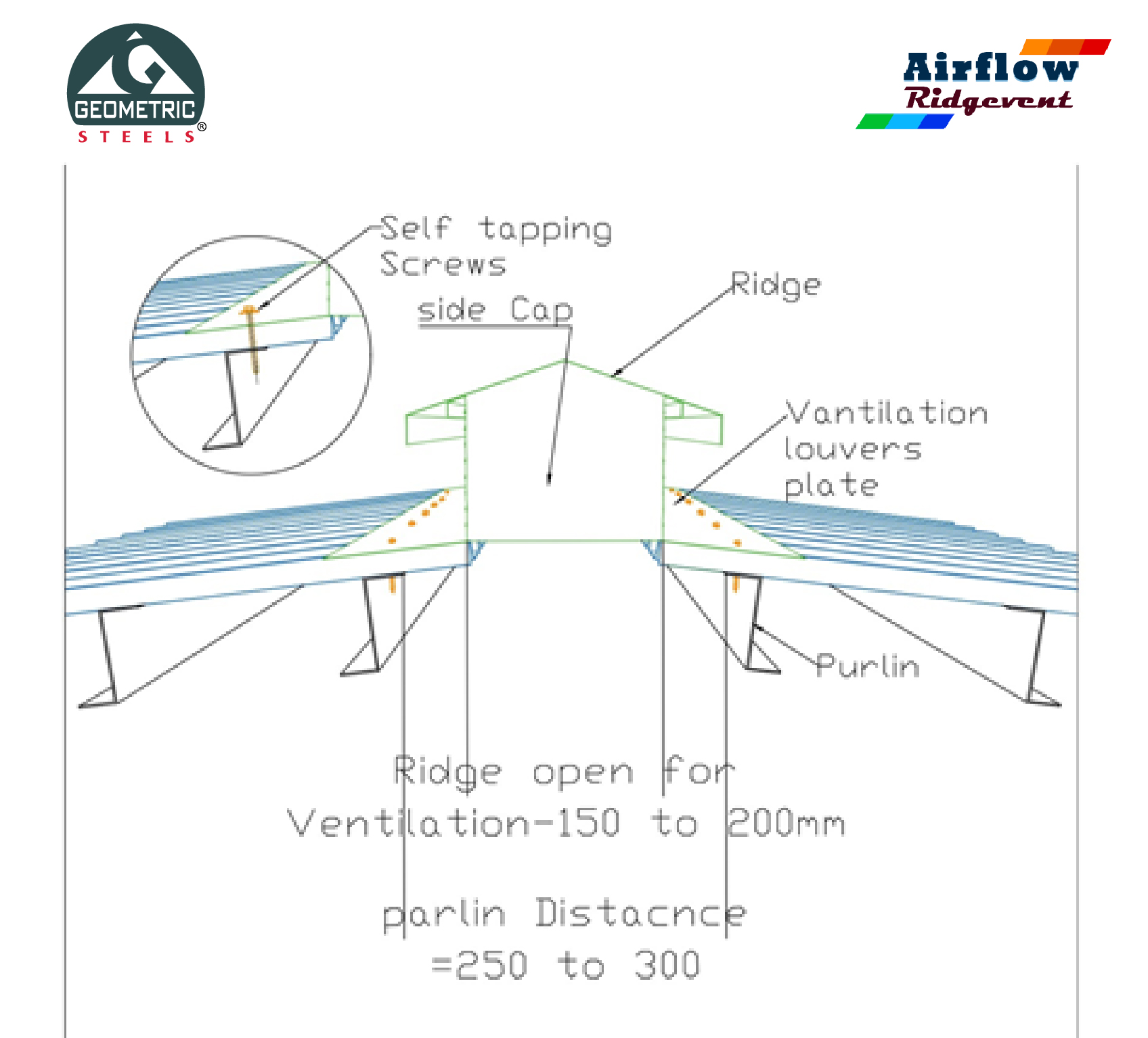

A Monitor-type Airflow Ridgevent that has two louvers that assemble vertically as exhaust plates as perpendicular system to the roof with a cavity Ridge that are colour coated galvanise. The Monitor type Airflow Ridgevent is pre pre-assembled device that can be installed on site directly

FEATURES AND BENEFITS

- High natural airflow

- Internal pressure of structures decreased.

- The profiles are available as Colour coated steel as well as all roofing profiles

- Improves & maintains a comfortable living environment

- No power, moving parts, or noise

- Maintenance-free (No clogging)

- Maintains a clean, attractive roofline

- Extends the life of the building through natural air circulation

- They are located exactly in the area where they are most good, which is at the highest point on the rooftop. Projected at the apex of the roof for maximum air circulation

- Easy to install on existing old roofing ALSO

- Maximum effective utilization of space with an existing arrangement of structure.

- Made in INDIA