Solving Heat Stress in Factories: A Case for Passive Roof Ridgevents

- Geometric Steels

- August 19, 2025

Solving Heat Stress in Factories: A Case for Passive Roof Ridgevents

Factory floors are the beating heart of production—but they can also be brutal environments when heat builds up. Workers, machines, and even the building itself suffer when hot air gets trapped under the roof. The result? Lower productivity, higher cooling costs, and in extreme cases, dangerous heat stress.

While mechanical ventilation and HVAC systems can help, they come with high installation and running costs. That’s where passive roof ridgevents step in—a simple, reliable, and energy-free solution for managing heat and improving air circulation in industrial spaces.

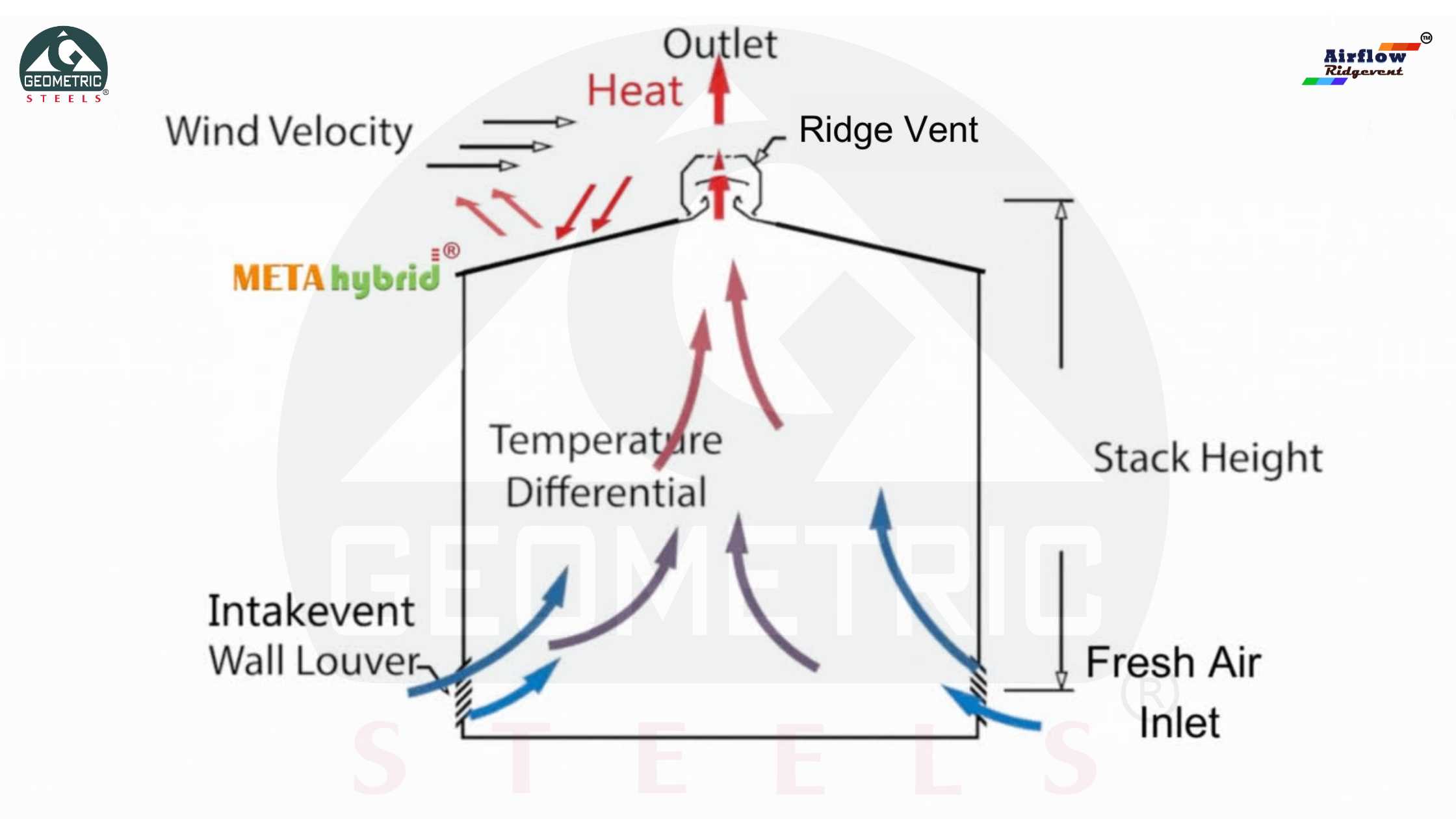

Why Passive Ventilation Works

Passive ridgevents use the natural forces of wind and temperature difference to remove hot, stale air from inside the building. Warm air rises toward the roof, where the ridgevent allows it to escape. At the same time, cooler air is drawn in through side openings, creating a continuous flow—no motors, no energy bills.

The effectiveness of this system depends on one key factor: air changes per hour (ACH). This measures how often the total volume of air inside the building is replaced. Different types of industrial spaces have different ACH requirements:

| Situation | Air Changes per Hour |

|---|---|

| Boiler Houses | 20 – 30 |

| Compressor Rooms | 30 – 60 |

| Engine Rooms | 20 – 30 |

| Factories (Workshops) | 6 – 10 |

| Furnace Shops | 30 – 60 |

| Garages | 8 – 12 |

| Kitchens (Commercial) | 15 – 20 |

| Laboratories | 4 – 6 |

| Machine Shops | 6 – 10 |

| Paint Shops | 30 – 60 |

| Poultry Houses | 6 – 10 |

| Warehouses | 4 – 8 |

Tip: In hotter regions, you should increase the ACH by at least two to effectively control temperature.

Choosing the Right Ridgevent Size

Getting ridgevent sizing right is essential. Too small, and the airflow won’t be enough to keep heat under control. Too big, and you risk unnecessary cost.

Step 1: Determine Building Usage

Start by identifying the building’s purpose and finding its ACH from the table above.

Example: A warehouse typically needs 4–8 ACH, while a boiler room might need 25–40 ACH.

Step 2: Calculate Ventilation Rate

Use the formula:

Q=L×W×H×A3600Q = \frac{L \times W \times H \times A}{3600}Q=3600L×W×H×AWhere:

- Q = Required airflow (m³/s)

- L = Building length (m)

- W = Building width (m)

- H = Average building height (m) = (Wall height + Ridge height) ÷ 2

- A = Required ACH

- 3600 = Conversion constant

Example:

A warehouse measuring 60m (L) × 30m (W) × 6m (H) with 8 ACH:

Q=60×30×6×83600=24 m³/sQ = \frac{60 \times 30 \times 6 \times 8}{3600} = 24 \text{ m³/s}Q=360060×30×6×8=24 m³/s

Step 3: Select Ridgevent Throat Size

Next, factor in effective stack height, wind velocity, and temperature difference to determine exhaust velocity from the manufacturer’s data. Divide Q by (ridgevent length × exhaust velocity) to get the required throat size.

The Benefits for Factory Heat Management

- No Energy Cost – Operates entirely on natural airflow.

- Year-Round Ventilation – Removes hot air in summer and stale air in winter.

- Improved Worker Comfort – Reduces heat stress, boosting morale and productivity.

- Low Maintenance – No motors, belts, or electrical parts to fail.

- Better Equipment Lifespan – Prevents overheating of machinery.

Airflow Ridgevent: Built for Industrial Efficiency

At Airflow Ridgevent, our focus is on delivering ventilation solutions that work silently, efficiently, and without consuming a single unit of electricity. Designed for industrial and commercial buildings, our ridgevents handle high air volumes while resisting weather infiltration.

We offer a range of models tailored to different structural needs:

- Hat Top Ridgevent – Compact and efficient, ideal for moderate ACH requirements.

- Monitor Type Ridgevent – Higher capacity design, perfect for heat-intensive operations.

- Onion Type Ridgevent – A robust design for heavy-duty airflow in demanding climates.

- Apex Ridgevent – Sleek profile for maximum ventilation without compromising roof aesthetics.

Each model is engineered to deliver optimal passive ventilation, reduce internal heat, and extend the lifespan of both workers’ productivity and the machinery they operate.

Case in Point: Hot Climate Factories

In regions where summer temperatures soar, heat stress can be a real productivity killer. Increasing ACH and installing ridgevents matched to the building’s needs can make a dramatic difference—not just for comfort, but for safety.

In one example, a manufacturing facility operating in 40°C+ weather reduced its indoor heat levels by several degrees simply by upgrading to larger-capacity passive ridgevents. The result? Lower energy use, happier workers, and better output.

Airflow ridgevents aren’t just an add-on—they’re a smart, cost-effective investment for any factory facing heat challenges. By understanding your building’s air change needs and sizing the ridgevent correctly, you can solve heat stress problems without adding a single unit to your power bill.

Contact Us

📞 +91 8550995556

📧 roof@geometricsteels.com

🌐 https://www.airflowridgevent.com/

Keywords: passive roof ventilation, factory heat control, industrial ventilation system, ridgevent sizing formula, air changes per hour, warehouse ventilation, hot climate factory cooling, industrial roof ridgevent, natural roof ventilation, airflow ridgevent products, hat top ridgevent, monitor type ridgevent, onion type ridgevent, apex ridgevent, passive ventilation for factories, energy-free ventilation system, reduce heat stress in factories, workshop ventilation design, furnace shop ventilation, industrial passive cooling, roof ventilation without power, ventilation rate calculation, improve air circulation in factories, sustainable industrial ventilation, high capacity roof ridgevent