The Science Behind Venturi Effect in Industrial Ridgevent Design

- Geometric Steels

- October 09, 2025

In industrial buildings, efficient ventilation isn’t just about comfort—it’s about maintaining air quality, temperature control, and worker safety. Factories, warehouses, and manufacturing plants generate continuous heat and fumes, making proper exhaust and air circulation critical.

This is where the Venturi effect becomes the foundation of passive ventilation systems such as the Airflow Ridgevent™ by Geometric Steels—a technology-driven approach that transforms natural wind movement into consistent, energy-free airflow.

Understanding the Venturi Effect

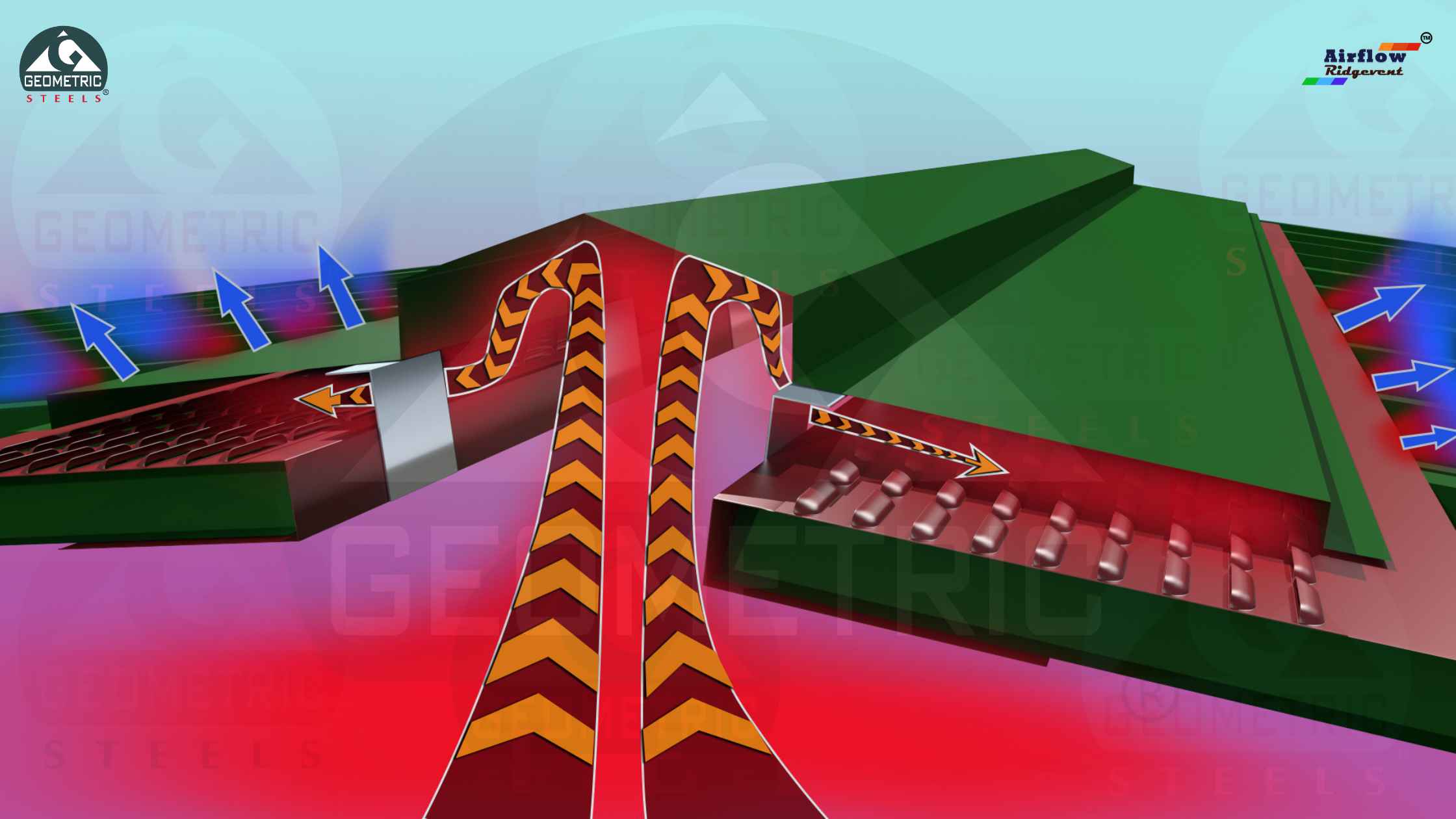

The Venturi effect is a principle of fluid dynamics that explains how air pressure decreases when air flows through a constricted passage, creating a suction effect. According to Bernoulli’s theorem, as the velocity of air increases, its pressure drops.

In simple terms: fast-moving air creates low pressure. When applied to ridgevent design, this effect helps continuously draw out hot, stale air from inside an industrial building, replacing it with fresh, cooler air from below.

This principle is the science behind every Ridgevent—ensuring smooth, continuous, and natural exhaust flow without depending on motors or electricity.

How the Venturi Effect Powers Industrial Ridgevents

When wind passes over the ridge of a building roof:

- Air acceleration: The ridgevent’s aerodynamic design narrows airflow, increasing wind velocity over the ridge.

- Pressure drop: The higher velocity creates a low-pressure zone at the ridgevent throat.

- Natural suction: The pressure difference pulls hot, humid air from the building upward through the ridge opening.

- Air replenishment: Cooler air enters from wall or eave louvers, forming a continuous air cycle.

This self-sustaining airflow system operates naturally, maintaining effective cross-ventilation even in low-wind conditions—thanks to the combined Venturi effect and stack effect.

Engineering the Air Cycle for Different Building Types

Each type of industrial structure demands a specific air change rate, measured as Air Changes per Hour (ACH). This determines how often the total volume of air inside a building is replaced within one hour.

| Building Type | Recommended ACH | Purpose |

|---|---|---|

| Boiler House | 20–30 | Heat and smoke removal |

| Furnace / Paint Shops | 30–60 | Fume extraction |

| Compressor Rooms | 30–60 | Continuous cooling |

| Machine Shops | 6–10 | Temperature balance |

| Warehouses | 4–8 | General air exchange |

| Laboratories | 4–6 | Controlled air quality |

| Poultry Houses | 6–10 | Odor and heat control |

Example: a warehouse measuring 60 m × 30 m × 6 m and requiring 8 air changes/hour needs:

Q = (L × W × H × A) / 3600 = (60 × 30 × 6 × 8) / 3600 = 24 m³/s

At a temperature difference of 6°C, this corresponds to an exhaust velocity of about 1.32 m/s—ideal for a 300 mm throat ridgevent. This example highlights how ridgevent throat size directly affects air circulation rate, ensuring optimal performance based on building volume and process heat levels.

Quick ACH & Airflow Calculator

Enter building details to estimate airflow (Q). Select ΔT, effective stack height, and wind to auto-suggest an exhaust velocity (editable). Then get an indicative throat opening per meter.

Results

- Volume (L×W×H): — m³

- Required flow Q: — m³/hr

- Required flow Q: — m³/s

- Indicative throat opening per meter: — mm

- Suggested ridgevent class: —

Note: Throat opening per meter is indicative for preliminary sizing only. Final selection depends on model geometry, rain baffles, net free area, and site wind conditions.

Designing for Optimum Ridgevent Performance

- Throat Size: Determines the effective opening area for exhaust. Larger throats accommodate higher air volumes.

- Stack Height: The vertical distance that drives buoyant air movement. Taller structures enhance natural draft.

- Wind Velocity: Even low wind speeds (around 2 m/s) can activate the Venturi suction effect, maintaining steady negative pressure above the ridge.

Advanced CFD (Computational Fluid Dynamics) analyses show that the geometry of the Airflow Ridgevent significantly influences airflow velocity and static pressure distribution, improving ventilation even under calm atmospheric conditions.

Types of Airflow Ridgevent by Geometric Steels

At Geometric Steels, we engineer ridgevent systems that merge aerodynamic efficiency with structural reliability. Each variant of our Airflow Ridgevent™ is designed to match specific airflow, temperature, and environmental requirements.

Hat Top Ridgevent

- Provides continuous natural airflow equal to multiple turbine ventilators per meter length.

- Designed for zero leakage, no maintenance, and long service life.

- Ridge-top installation suitable for solar-integrated roofs.

Best for: industrial workshops, plants, and fabrication units needing consistent ventilation.

Monitor Type Ridgevent

- Dual louver design enables maximum cross-ventilation and airflow.

- Lightweight, pre-fabricated, and easy to install.

- Ensures effective smoke and heat removal without mechanical components.

Best for: logistics centers, high-roof factories, and large commercial structures.

Onion Type Ridgevent

- Works purely on thermal and natural air convection.

- Ideal for low- to medium-temperature industries.

- Features a self-draining profile that prevents rainwater entry.

Best for: warehouses, boiler rooms, and compressor enclosures.

Apex Ridgevent

- Custom-engineered on-site with dual-frame construction for structural strength.

- Designed for large-span roofs with integrated water flow guides.

- Compatible with both metal and polycarbonate roofing systems.

Best for: large industrial buildings and manufacturing complexes.

Why Venturi-Based Ridgevents Are the Smart Choice

- 100% natural airflow with zero power consumption.

- Continuous, uniform air extraction along the ridge line.

- Improved air quality and reduced heat load.

- Balanced internal pressure reduces structural strain.

- Minimal maintenance, maximum durability.

- Aligns with sustainable, energy-efficient building practices.

Driving Smarter Ventilation Through Airflow Ridgevent

The Venturi effect is more than aerodynamic theory—it’s the science behind effective industrial ventilation. By leveraging natural air pressure and smart ridgevent design, Geometric Steels’ Airflow Ridgevent™ series ensures consistent airflow, lower indoor temperature, and a healthier workspace—all without consuming a single watt of electricity.

From Hat Top to Apex Ridgevent, every product is engineered for performance, reliability, and sustainability—making it the preferred choice for engineers, architects, consultants, and industry leaders seeking future-ready ventilation solutions.

Contact Us

For design consultation or customized ridgevent solutions:

📞 +91-85509 95556

📧 roof@geometricsteels.com

🌐 www.geometricsteels.com |

https://airflowridgevent.com/onion-type-airflow-ridgevent.php

Keywords: ridgevent, industrial ridgevent, airflow ridgevent, metal roof ridgevent, passive ventilation, natural roof ventilation system, ventilation for factories, hat top ridgevent, monitor ridgevent, onion type ridgevent, apex ridgevent, ridgevent manufacturer India, thermal ventilation, natural airflow system, roof exhaust design, geometric steels ridgevent, ridgevent, ridge vent roof, metal roof ridge vent